What we offer

We are the biggest foundry in our region and we have been here since 1924 …

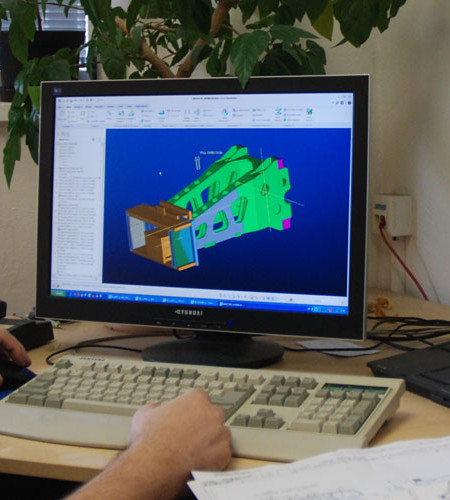

Technological preparation and consultancy

Our specialists, in cooperation with customer’s engineers are able to find an optimal solution of the casting costruction and to recommend a most suitable material for its production, achieving significant cost savings.

Find out morePattern shop

In our in-house pattern shop we produce patterns in quality H1 according to ČSN EN12890/DIN 1511.

Find out moreMoulding lines

Our technology allows us to produce castings from 30 kg to 12 000 kg. In order to offer the production of such a wide weight range at a competitive price we are equipped with three different moulding lines.

Find out moreMaterials and Furnaces

We continuously improve both the production process and the range of products, our goal is maximum customer satisfaction.

Find out moreMachining

Rough or final machining in tollerance 0,1 – 0,05 mm is provided in our in-house machining shop; the final precise machining and grinding in tollerance of 0,005 mm is outsourced by the company TAJMAC-ZPS, a.s. which is a professionally equipped machining supplier located in our common area.

Find out moreQuality assurance

Quality system

Department of Quality Control is independent from other production compartments. It ensures the fulfilment of customer requirements, supervision of production process and maintenance of quality management policy of our company.

Labs and Test rooms

Our labs and test rooms provide quality control of castings manufacturing process and offer free capacity to carry out various tests for external customers.

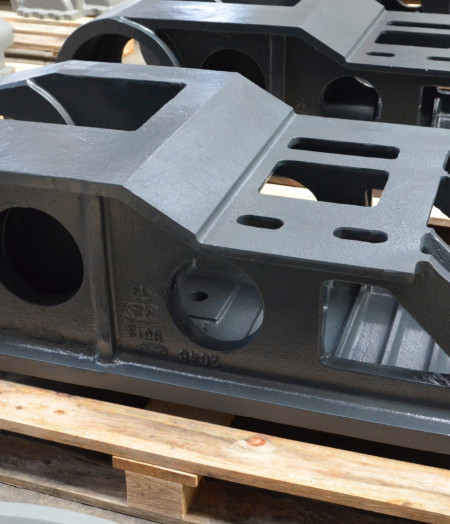

Clamping elements

We offer clamping elements in standard models (A-J), but according to your requirement we are able to offer original solutions from individual elements to their assemblies. Thanks to our experience we are ready to contribute to our customers in the field of materials and optimal construction.

Find out more